DIGITAL FLEET MAINTENANCE SERVICES (DF-MAS STAGE II)

Year: 2023 | Promoters: MINISTERIO DE INDUSTRIA, COMERCIO Y TURISMO / PLAN DE RECUPERACIÓN, TRANSFORMACIÓN Y RESILIENCIA / NEXT GENERATION EU

Firms: BIM6D / OnTech Innovation Cluster / Grupo Azvi / Cenit / Datagram

PROJECT EXPLANATION

The project proposees the digitalization of the maintenance service of a fleet of machinery used in the conservation of railway infrastructure. This fleet includes: tampers, profilers, scrapers, stabilizers, trains and wagons. They are heavy machines, of high technical complexity since they contain different systems and subsystems (operation, traction and auxiliary) and are subject to highly demanding working conditions and therefore to a high level of wear with high failure rates. , which means high maintenance and operation costs (OPEX). The maintenance of the fleet is carried out in the workshop, so the digitalization of the service includes both the analysis of the machines and the analysis of the facilities and the technical and human resources of the workshop itself.

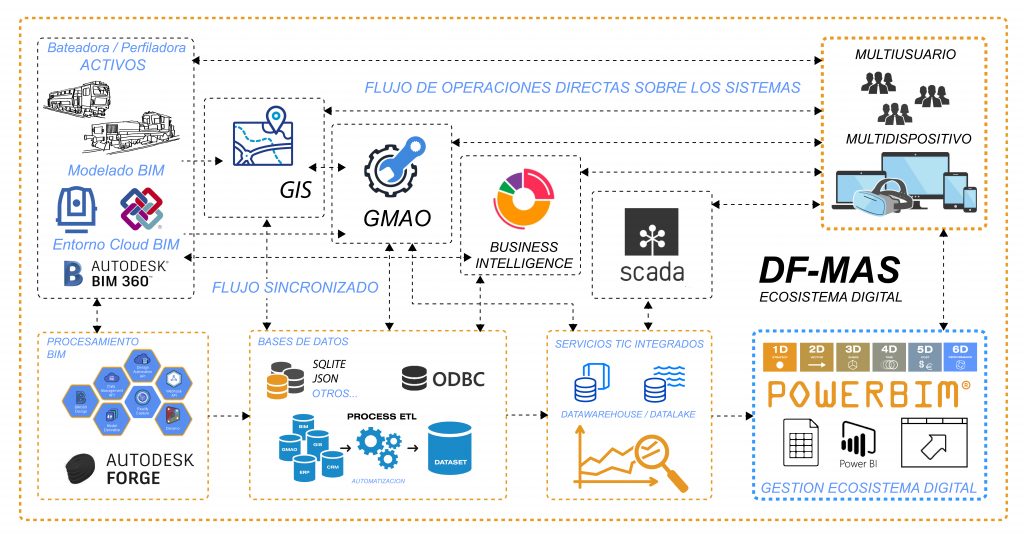

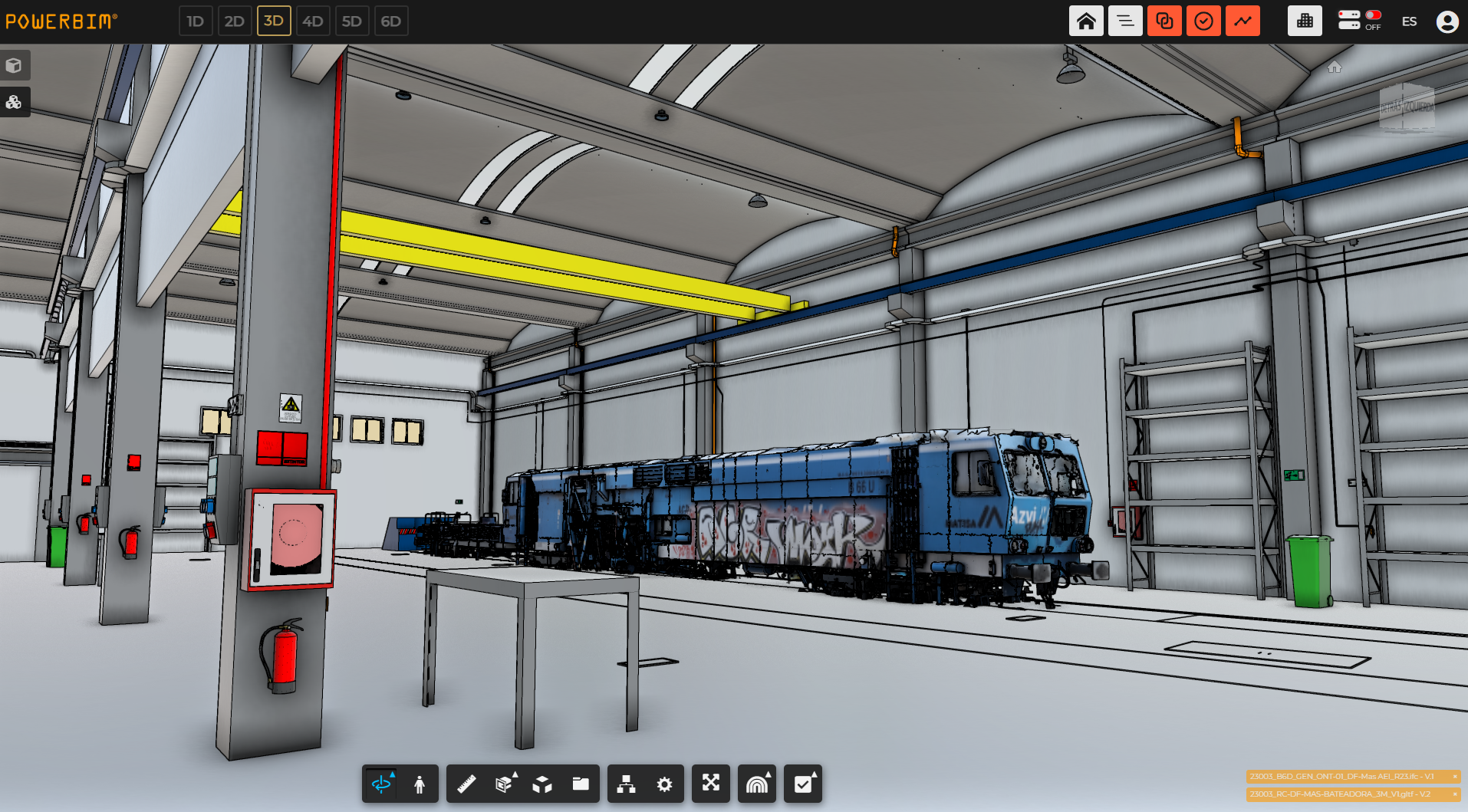

This phase incorporates BIM technology into the DF-MAS strategy. Thanks to this, the modeling of objects such as GD will have all the data representation and standardization capacity that this technology provides as one of its main advantages. Phase 2 of the DF-MAS project includes digitization, BIM management with CDE (Collaborative Common BIM Environment) and deployment of BIM-based DigitalTwin (POWERBIM) integrated with the IoT data input-output management solutions and platform architecture previously developed in Phase 1 of the project.

GOAL 1

Data collection process:

- Site visit to take images and video recording.

- Scanning through point clouds.

GOAL 2

Modelling process:

- BIM modelling of the workshop building and export to IFC format.

- 2.2) Generation of a digital twin of the engine (3D object in GLTF format), using virtual reality capture software.

- Generation of the necessary parameters for the further processing of data provided by the client.

GOAL 3

DigitalTwin integration with POWERBIM:

- Integration in POWERBIM of IFC model of the workshop, as well as the digital twin of the machinery in GLTF format, for further merging.

- Generation of interactive report for the correct visualisation of the data obtained.

- Integration of maintenance inventory (CMMS System)

- Integration of realtime data coming from DataLake Systems